Introduction

In today’s competitive manufacturing landscape, maintaining optimal inkjet printer performance isn’t just about preventing downtime—it’s about protecting your bottom line. Whether you’re running DTF printers for textile applications, UV printers for signage, or industrial-grade inkjet systems for packaging, a well-maintained printer can mean the difference between meeting production deadlines and facing costly delays.

After working with hundreds of B2B clients across various industries, I’ve observed that companies with structured inkjet maintenance programs typically see 40% fewer breakdowns, 25% longer equipment lifespan, and significantly lower per-unit printing costs. This comprehensive guide will walk you through the essential maintenance practices that separate successful operations from those constantly battling equipment issues.

The key to effective inkjet maintenance lies in understanding that these sophisticated machines require consistent attention across multiple systems: ink delivery, printhead technology, substrate handling, and environmental controls. Each component plays a crucial role in maintaining print quality and operational reliability.

Understanding Your Inkjet Printer’s Critical Components

Printhead Systems: The Heart of Quality Output

Modern inkjet printers rely on precision-engineered printheads that operate at microscopic tolerances. Whether you’re using piezoelectric or thermal inkjet technology, these components demand specific maintenance protocols to maintain their 600-1440 DPI capabilities.

Piezoelectric Printheads (common in Epson-based systems):

- Feature individual crystals that control each nozzle

- Require gentle cleaning solutions to prevent crystal damage

- Typically last 6-12 months with proper maintenance

- Vulnerable to dried ink and contamination

Thermal Printheads (found in HP and Canon systems):

- Use heating elements to create ink bubbles

- More resilient to cleaning chemicals

- Generally have shorter lifespan (3-6 months in heavy use)

- Sensitive to temperature fluctuations

Ink Delivery Systems: Maintaining Flow Consistency

The ink delivery system encompasses everything from bulk ink tanks to the fine capillary tubes feeding your printheads. Understanding pressure dynamics, filtration requirements, and flow rates is essential for preventing the most common inkjet maintenance issues.

Critical Components:

- Primary ink tanks and secondary cartridges

- Pressure regulation systems

- Inline filters and dampers

- Tube networks and fittings

- Waste ink collection systems

Substrate Handling Mechanisms

Often overlooked in basic maintenance routines, substrate handling systems directly impact print quality and equipment longevity. Poor substrate path maintenance leads to media jams, print head strikes, and inconsistent registration.

Daily Inkjet Maintenance Protocols

Morning Startup Routine (15-20 minutes)

Visual Inspection Checklist:

- Ink Level Verification: Check all primary tanks and secondary cartridges. Most industrial inkjet systems should maintain ink levels above 25% to prevent air introduction into the system.

- Printhead Nozzle Check: Run nozzle check patterns on all color channels. Look for missing nozzles, deflected jets, or inconsistent density. Document any anomalies in your maintenance log.

- Substrate Path Inspection: Remove any debris from feed mechanisms, check belt tension, and verify alignment guides are properly positioned.

- Environmental Conditions: Verify temperature (18-25°C) and humidity (45-65% RH) are within specification. Extreme conditions are the leading cause of preventable inkjet maintenance issues.

Cleaning Sequence: Begin with a light printhead cleaning cycle using manufacturer-approved cleaning solutions. Avoid over-cleaning, which can damage delicate nozzle structures. For most industrial applications, a light cleaning every morning and thorough cleaning weekly provides optimal balance.

End-of-Shift Procedures (10-15 minutes)

Printhead Protection Protocol: If your operation runs multiple shifts, implement a printhead capping routine between shifts. Proper capping prevents ink drying in nozzles and maintains optimal firing chamber conditions.

System Purge Considerations: For facilities with extended downtime (weekends, holidays), consider implementing purge routines with cleaning fluid or maintenance cartridges. This prevents ink settling and maintains system pressure balance.

Weekly Deep Maintenance Procedures

Comprehensive Printhead Service

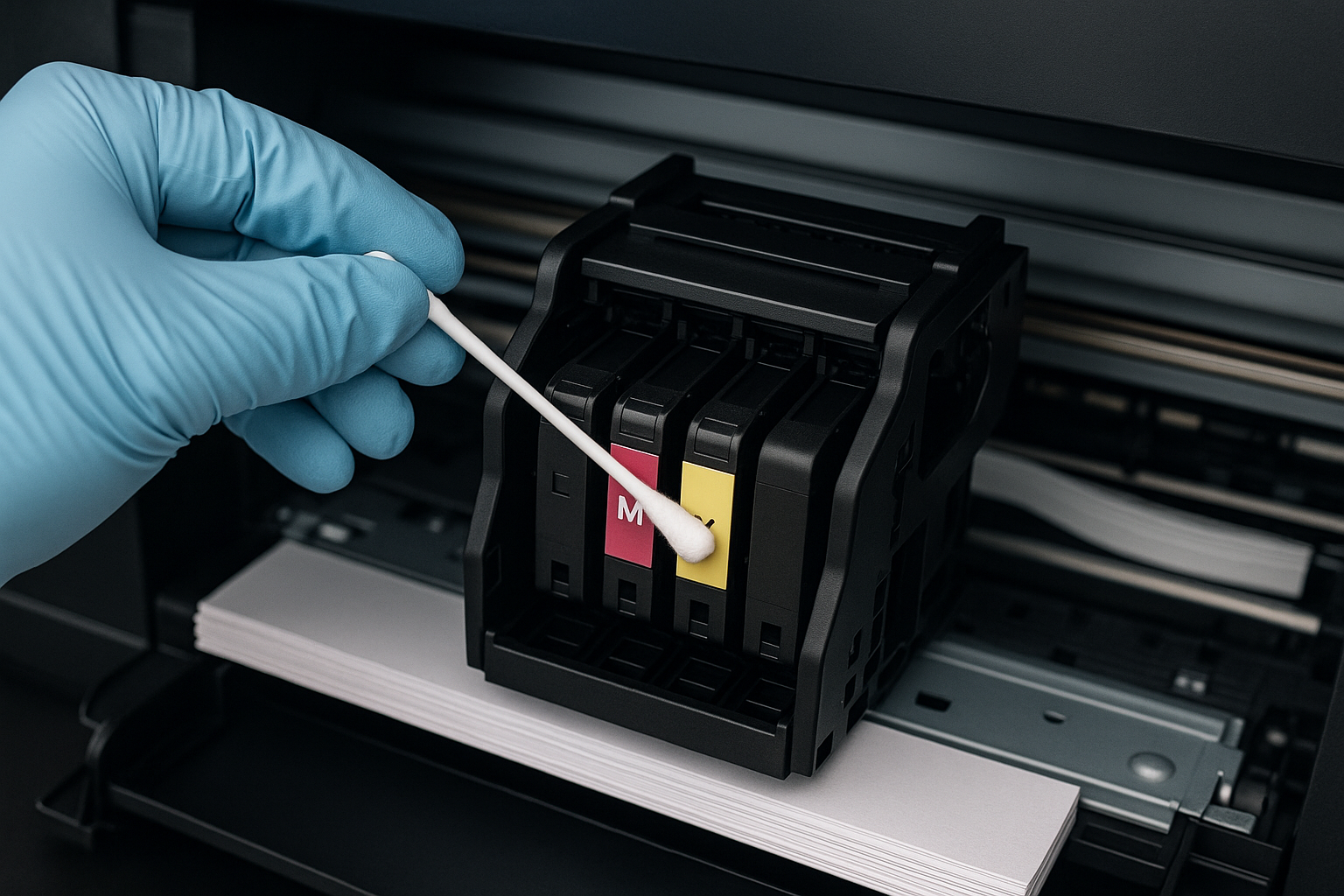

Advanced Cleaning Techniques: Every week, perform thorough printhead maintenance beyond basic cleaning cycles. This involves:

- Ultrasonic Cleaning (when applicable): Remove printheads according to manufacturer specifications and clean in ultrasonic baths with appropriate solutions. This removes stubborn ink deposits that standard cleaning cycles can’t address.

- Manual Nozzle Inspection: Use magnification tools to inspect individual nozzles for damage, debris, or ink buildup. Document any patterns of degradation.

- Pressure Test Verification: Check ink delivery pressure at the printhead using calibrated gauges. Pressure variations indicate filter clogs or pump degradation.

Ink System Maintenance

Filter Replacement Schedule: Replace inline filters based on throughput rather than time intervals. High-volume operations may require weekly filter changes, while lower-volume applications can extend to monthly replacements.

Line Purging Procedures: Weekly line purging prevents ink settling and maintains consistent viscosity throughout the delivery system. Use manufacturer-specified purging sequences to avoid cross-contamination between color channels.

Mechanical System Service

Belt and Drive Maintenance: Inspect substrate handling belts for wear, proper tension, and alignment. Replace or adjust as needed to prevent registration issues and media jams.

Encoder Strip Cleaning: Clean linear encoder strips with lint-free cloths and isopropyl alcohol. Contaminated encoders cause banding, registration errors, and reduced print quality.

Monthly Preventive Maintenance Program

Environmental System Optimization

HVAC System Integration: Monthly verification of environmental controls ensures optimal printing conditions. Check air filtration systems, humidity control mechanisms, and temperature stability across the print zone.

Contamination Prevention: Implement monthly deep cleaning of the printer environment, including floors, walls, and ceiling areas around equipment. Airborne contaminants are a major contributor to printhead degradation and print quality issues.

Calibration and Alignment Procedures

Color Calibration: Perform comprehensive color calibration using standardized test targets. Document color consistency across the print width and maintain calibration records for quality control purposes.

Media Advance Calibration: Verify substrate advance accuracy using precision measurement tools. Incorrect media advance causes banding and color registration issues that affect final product quality.

Wear Component Assessment

Consumable Parts Inventory: Maintain adequate inventory of critical wear components:

- Printhead assemblies

- Ink filters and dampers

- Drive belts and tensioning mechanisms

- Cleaning supplies and maintenance cartridges

Predictive Replacement Planning: Track component usage hours and implement replacement schedules before failure occurs. This proactive approach prevents unexpected downtime and maintains consistent production capacity.

Advanced Maintenance Techniques for Industrial Applications

Printhead Life Extension Strategies

Temperature Management: Implement advanced temperature control systems that maintain printhead operating temperatures within ±2°C of optimal. Temperature stability directly correlates with printhead longevity and print consistency.

Ink Formulation Considerations: Work with ink suppliers to optimize formulations for your specific application requirements. Lower viscosity inks reduce printhead stress but may require adjusted curing parameters.

System Performance Monitoring

Data-Driven Maintenance: Implement monitoring systems that track:

- Print head firing frequency per nozzle

- Ink consumption rates by color

- Environmental condition variations

- Error frequency and types

Predictive Analytics Integration: Advanced operations can implement IoT sensors and analytics platforms that predict maintenance needs before issues affect production. This approach reduces maintenance costs by 30-50% compared to reactive maintenance strategies.

Troubleshooting Common Maintenance-Related Issues

Addressing Persistent Nozzle Problems

When standard cleaning procedures fail to resolve nozzle issues, systematic troubleshooting is required:

- Pressure Analysis: Verify ink delivery pressure matches specifications

- Contamination Assessment: Check for foreign particles in ink supply

- Environmental Factors: Confirm temperature and humidity stability

- Electrical Verification: Test printhead driver signals and timing

Resolving Ink Flow Irregularities

Inconsistent ink flow often stems from:

- Partially clogged filters reducing pressure

- Air bubbles in supply lines

- Improper ink viscosity due to temperature variations

- Worn pump components affecting pressure consistency

Cost-Benefit Analysis of Preventive Maintenance

Financial Impact Assessment

Direct Cost Savings:

- Reduced unplanned downtime: $500-2000 per hour depending on operation scale

- Extended printhead life: 25-40% longer service intervals

- Lower ink consumption: 10-15% reduction through optimized delivery systems

- Decreased labor costs: Fewer emergency repair situations

Indirect Benefits:

- Improved customer satisfaction through consistent delivery schedules

- Enhanced product quality reducing waste and rework

- Better inventory management through predictable replacement cycles

- Reduced insurance claims from equipment damage

ROI Calculation Framework

For a typical mid-scale industrial inkjet operation:

- Monthly maintenance investment: $800-1200

- Prevented downtime value: $3000-5000

- Extended component life savings: $1500-2500

- Quality improvement benefits: $1000-2000

Net monthly benefit: $4700-8300 Annual ROI: 400-700%

Building Your Maintenance Team and Protocols

Training and Certification Requirements

Technical Skill Development: Ensure maintenance staff receive proper training on:

- Printhead handling and replacement procedures

- Ink system service and troubleshooting

- Environmental control system operation

- Safety protocols for chemical handling

Certification Programs: Many manufacturers offer certification programs that provide:

- Advanced troubleshooting techniques

- Access to technical support resources

- Warranty compliance verification

- Updated maintenance procedures

Documentation and Record Keeping

Maintenance Log Requirements: Maintain detailed records including:

- Daily inspection results

- Cleaning cycle frequency and results

- Component replacement dates and part numbers

- Environmental condition logs

- Print quality assessments

Digital Documentation Systems: Implement digital maintenance management systems that provide:

- Automated scheduling and reminders

- Historical trend analysis

- Inventory management integration

- Compliance reporting capabilities

Conclusion and Action Plan

Effective inkjet maintenance is not optional in today’s competitive manufacturing environment—it’s a critical business strategy that directly impacts profitability, customer satisfaction, and operational efficiency. The maintenance protocols outlined in this guide represent industry best practices developed through years of real-world application across diverse industrial environments.

Immediate Action Items:

- Assessment Phase: Evaluate your current maintenance practices against the standards outlined in this guide

- Planning Phase: Develop a structured maintenance schedule appropriate for your operation scale

- Implementation Phase: Begin with daily and weekly protocols while planning monthly procedures

- Optimization Phase: Implement monitoring systems and refine procedures based on performance data

Key Success Factors:

- Consistency in maintenance execution

- Proper staff training and accountability

- Quality documentation and record keeping

- Proactive rather than reactive approach

- Regular review and optimization of procedures

Remember that inkjet maintenance is an investment, not an expense. Operations that implement comprehensive maintenance programs consistently outperform those using reactive approaches by significant margins in both cost control and production reliability.

The next step is implementing these practices systematically in your operation. Start with the daily protocols, establish consistency, then gradually implement the more advanced monthly and predictive maintenance procedures. Your equipment, your team, and your bottom line will reflect the benefits of this professional approach to inkjet maintenance.