Meta Information

- Target Keyword: inkjet printing technology

- Secondary Keywords: what is inkjet printing, inkjet printer basics, beginner guide inkjet

- Word Count: ~2,800 words

- Content Type: Beginner’s Guide

Last week, I was sitting in a coffee shop when I overheard two entrepreneurs discussing their new t-shirt business. “We need a printer,” one said, “but I have no idea what inkjet even means.” Sound familiar? Don’t worry – we’ve all been there.

If you’re just starting to explore the world of digital printing, the terminology can feel overwhelming. Inkjet this, thermal that, piezo something-or-other. But here’s the thing: understanding inkjet printing technology doesn’t require an engineering degree. In fact, once you grasp the basics, you’ll wonder why it seemed so complicated in the first place.

After spending over 12 years helping businesses choose their first printing equipment, I’ve learned that the best way to explain inkjet technology is to start with what you already know – and build from there.

What Exactly is Inkjet Printing Technology?

Let’s start with the basics. Inkjet printing is a method of recreating digital images by propelling tiny droplets of liquid ink onto paper, fabric, or other materials. Think of it as a controlled spray paint system, but instead of covering everything in one color, it precisely places millions of microscopic dots to create detailed images.

The “inkjet” name comes from the fact that the printer literally jets (or shoots) ink onto the printing surface. Pretty straightforward, right?

But here’s where it gets interesting: not all inkjet printers work the same way. There are actually several different technologies hiding under that “inkjet” umbrella, each with its own strengths and ideal applications.

The Two Main Types of Inkjet Technology

When I first started in this industry, I thought all inkjet printers were basically the same. Boy, was I wrong! There are two primary technologies that drive inkjet printing:

1. Thermal Inkjet (Also Called Bubble Jet) This is probably what most people think of when they picture inkjet printing. Thermal inkjet printers use heat to create tiny bubbles in the ink, which then burst and propel ink droplets onto the paper.

Here’s how it works in simple terms:

- A tiny heating element (smaller than a human hair) heats the ink

- The ink forms a bubble and expands rapidly

- The bubble bursts, shooting a droplet of ink toward the paper

- The bubble collapses, creating a vacuum that draws fresh ink into the chamber

Companies like HP and Canon have built their desktop printer empires on this technology. It’s relatively inexpensive to manufacture and produces excellent results for everyday printing needs.

2. Piezoelectric Inkjet This technology uses a completely different approach. Instead of heat, piezoelectric printers use a crystal that changes shape when electricity is applied to it.

The process looks like this:

- An electric current is applied to a piezoelectric crystal

- The crystal flexes, creating pressure in the ink chamber

- This pressure forces a precise droplet of ink through the nozzle

- The crystal returns to its original shape, refilling the chamber

Epson has been the biggest proponent of this technology, and for good reason. Piezoelectric systems offer more precise control over droplet size and can handle a wider variety of inks, including specialized formulations for textile and industrial applications.

Why Should You Care About Inkjet Technology?

Now, you might be thinking, “This is all fascinating, but why does it matter to me?” Great question! Understanding inkjet technology helps you make better decisions about which printer to buy, how to maintain it, and what results to expect.

Let me share a story that illustrates this perfectly. Last year, I worked with a small business owner named Jennifer who wanted to start a custom apparel business. She walked into my office with a simple question: “I need a printer that can print on t-shirts. What should I buy?”

If I had just sold her the first inkjet printer I could think of, she would have been disappointed. Desktop inkjet printers – while excellent for paper – simply can’t handle the specialized inks and processes required for textile printing.

Instead, we discussed her specific needs and found that a DTG (Direct-to-Garment) printer with piezoelectric technology would be perfect for her business. Six months later, she’s processing dozens of orders weekly and couldn’t be happier with her choice.

The point? Different inkjet technologies excel at different applications. Understanding these differences helps you choose the right tool for your specific needs.

The Evolution of Inkjet Technology

Inkjet printing has come a long way since its invention in the 1970s. Back then, the technology was primitive, slow, and produced relatively low-quality results. Today’s inkjet printers can produce photographic-quality images, print on virtually any material, and operate at speeds that would have been unimaginable just a decade ago.

Key Milestones in Inkjet Development

1970s: The first inkjet printers were developed, primarily for industrial marking applications.

1980s: Consumer inkjet printers emerged, though they were expensive and limited in capability.

1990s: Color inkjet printing became affordable for home users, revolutionizing personal printing.

2000s: Photo-quality inkjet printing became standard, with specialized photo papers and six-color ink systems.

2010s: Industrial inkjet applications exploded, with printers capable of handling textiles, ceramics, and even 3D objects.

2020s: We’re now seeing AI-powered ink optimization, eco-friendly formulations, and printers that can handle everything from business cards to building-sized graphics.

Common Inkjet Applications You Should Know About

One of the beautiful things about inkjet technology is its versatility. Here are the most common applications I encounter in my daily work:

1. Office and Home Printing

This is the most familiar application. Your typical desktop inkjet printer handles documents, photos, and general-purpose printing. These printers usually use thermal inkjet technology and are designed for convenience rather than speed or specialized applications.

2. Photo Printing

Specialized photo inkjet printers use additional colors (often 6, 8, or even 12 different inks) to achieve exceptional color accuracy and smooth gradations. Many professional photographers rely on these systems for their final prints.

3. Large Format Printing

When you need to print banners, posters, or architectural drawings, large format inkjet printers are the go-to solution. These machines can handle rolls of material several feet wide and produce stunning results.

4. Textile Printing

This is where things get really interesting. DTG (Direct-to-Garment) printers can print full-color designs directly onto t-shirts, hoodies, and other garments. DTF (Direct-to-Film) printers create transfers that can be applied to virtually any fabric.

5. Industrial and Commercial Applications

From printing on packaging materials to creating custom labels, industrial inkjet systems handle high-volume production with remarkable efficiency.

Understanding Ink Types and Their Impact

Not all inks are created equal, and the type of ink your printer uses significantly impacts both the printing process and the final results. Here’s what you need to know:

Dye-Based Inks

These inks are made of colorants that are completely dissolved in liquid. They produce vibrant colors and are excellent for photo printing, but they’re not as long-lasting as other ink types.

Pros:

- Brilliant, vibrant colors

- Relatively inexpensive

- Good for photo printing

Cons:

- Prone to fading over time

- Not waterproof

- Can bleed on certain materials

Pigment-Based Inks

Pigment inks contain tiny particles of colorant suspended in liquid. They’re more durable than dye-based inks but can sometimes appear less vibrant.

Pros:

- Excellent longevity

- Better water resistance

- More suitable for archival printing

Cons:

- Can be more expensive

- Sometimes less vibrant than dye inks

- May require special papers for best results

Specialized Inks

The world of inkjet printing has exploded with specialized ink formulations:

- Textile inks: Designed to bond with fabric fibers

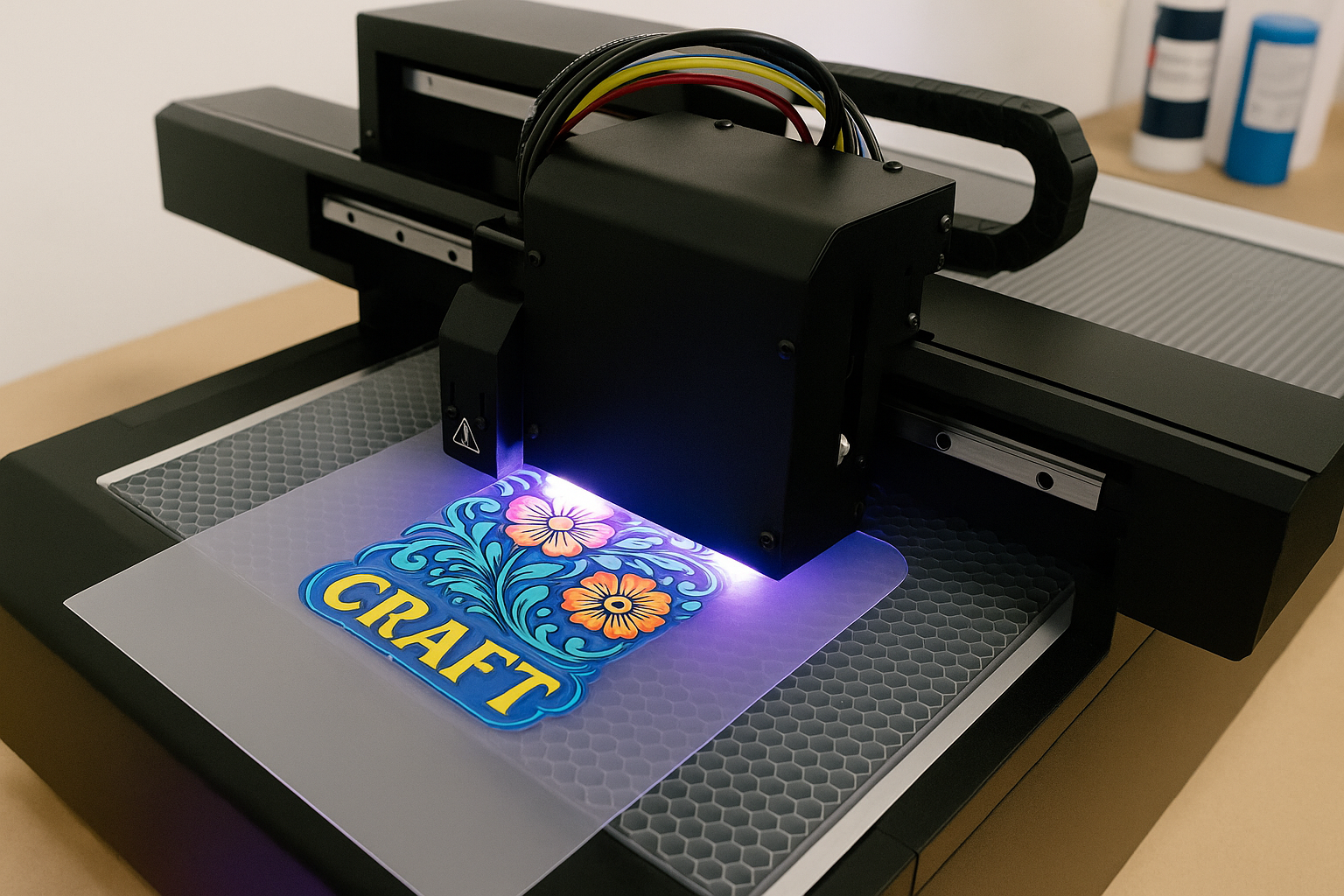

- UV-curable inks: Harden when exposed to UV light, creating extremely durable prints

- Eco-solvent inks: Environmentally friendly inks for outdoor applications

- Sublimation inks: Transfer to materials through heat and pressure

Key Advantages of Inkjet Technology

Why has inkjet printing become so dominant? Here are the main advantages that make it attractive for both consumers and businesses:

1. Versatility

Inkjet printers can handle an incredible range of materials – from traditional paper to fabrics, plastics, metals, and even wood. This versatility makes them ideal for businesses that need to print on multiple substrates.

2. Cost-Effectiveness

For small to medium print runs, inkjet printing is often more economical than traditional printing methods. There are no plates to make, no setup costs, and you can print just one copy if needed.

3. Quality

Modern inkjet printers can produce results that rival traditional printing methods. With resolutions reaching 2400 dpi or higher, the quality is exceptional for most applications.

4. Speed of Setup

Unlike offset printing, which requires extensive setup time, inkjet printing can begin almost immediately. This makes it perfect for on-demand printing and quick turnarounds.

5. Customization

Every print can be different. This capability has revolutionized industries like packaging, where personalized designs are increasingly important.

Common Misconceptions About Inkjet Technology

In my years of working with clients, I’ve encountered several persistent myths about inkjet printing. Let me set the record straight:

Myth 1: “Inkjet Prints Always Fade Quickly”

This was true for early inkjet printers, but modern pigment-based inks can last decades when properly stored. I’ve seen inkjet prints from 15 years ago that still look vibrant today.

Myth 2: “Inkjet is Only for Small-Scale Printing”

Industrial inkjet systems can handle massive production volumes. Some newspaper printing operations now use inkjet technology for their daily runs.

Myth 3: “Inkjet Prints Are Always Expensive”

While ink costs can add up, the total cost per print (including setup, materials, and labor) is often lower than alternatives for short to medium runs.

Myth 4: “All Inkjet Printers Are the Same”

As we’ve discussed, there are significant differences between thermal and piezoelectric systems, not to mention the vast array of specialized inkjet applications.

What to Consider When Choosing Inkjet Technology

If you’re thinking about investing in inkjet printing equipment, here are the key factors to consider:

1. Application Requirements

What will you be printing? Documents? Photos? Textiles? The application determines everything else about your printer choice.

2. Volume Expectations

How much printing will you do? High-volume applications may justify more expensive equipment with lower per-page costs.

3. Material Compatibility

Different printers handle different materials. Make sure your chosen system can work with your intended substrates.

4. Quality Requirements

Do you need photo-quality output, or will good business-quality suffice? Higher quality usually means higher costs.

5. Budget Considerations

Remember to factor in ongoing costs like ink, maintenance, and replacement parts, not just the initial purchase price.

The Future of Inkjet Technology

Where is inkjet printing heading? Based on current trends and my conversations with industry leaders, here’s what I see coming:

Sustainability Focus

Environmental concerns are driving innovation in eco-friendly inks and energy-efficient printing processes. Water-based inks and renewable energy-powered systems are becoming more common.

AI Integration

Smart printers that can optimize ink usage, predict maintenance needs, and automatically adjust settings for different materials are already appearing in high-end systems.

Expanded Material Compatibility

Research is ongoing into inks that can print on previously impossible materials, including living tissues for medical applications and even food products.

Speed Improvements

Industrial inkjet systems are getting faster every year, with some now capable of printing hundreds of square meters per hour.

Getting Started with Inkjet Printing

Ready to dive into the world of inkjet printing? Here’s my advice for beginners:

1. Start with Your Needs

Don’t get overwhelmed by all the options. Focus on what you actually need to print and work backward from there.

2. Do Your Research

Talk to other users, read reviews, and don’t be afraid to ask questions. Most manufacturers offer demos or trial periods.

3. Consider Total Cost of Ownership

Look beyond the initial purchase price. Factor in ink costs, maintenance, and potential downtime.

4. Plan for Growth

Choose a system that can grow with your needs. It’s often better to invest in slightly more capability than you need today.

5. Get Proper Training

Whatever system you choose, make sure you understand how to operate and maintain it properly. Good training pays for itself quickly.

Conclusion

Inkjet printing technology has transformed from a simple office convenience into a powerful tool that’s revolutionizing industries worldwide. Whether you’re printing family photos, creating custom apparel, or running a commercial print shop, understanding the basics of inkjet technology helps you make better decisions and achieve better results.

Remember, the best inkjet printer isn’t necessarily the most expensive one – it’s the one that meets your specific needs at a price you can afford. Take time to understand your requirements, research your options, and don’t hesitate to seek expert advice when needed.

The world of inkjet printing is vast and constantly evolving, but with this foundation, you’re well-equipped to explore it confidently. Whether you’re just starting out or looking to expand your capabilities, inkjet technology offers solutions that can help you achieve your goals.

Have questions about inkjet printing technology? I’d love to help. Feel free to reach out through our contact form or follow us on social media for more printing insights and tips.